BACKGROUND

Cadent own and operate the Lincoln to Scopwick high pressure gas pipeline built in 1969 (PSR number 1189). This is classified as a Major Accident Hazard Pipeline (MAHP) by the Pipeline Safety Regulations 1996.

Cadent are the UK’s largest gas distribution company managing a network of more than 80,000 miles of pipelines which transports gas to 11 million customers nationwide.

The Scopwick pipeline contained welds of unknown quality and therefore classified within requirements of T/PM/P/18.

A section of the pipeline was routed in close proximity to the west of Dunston Quarry which is owned by a Plant Hire company.

The quarry is situated approximately 11 km to the south-east of Lincoln and is 1.2 km north-west from the village of Dunston. It has been worked for at least 20 years for production of limestone.

At some point, between 2007 and 2012, Dunston Quarry was extended westwards from a previous stand-off distance of approximately 50m (from the pipeline) to a much closer distance of around 6m (between the pipeline and quarry boundary fence).

Following a Cadent audit in February 2016, it was found that the western face of the quarry was too steep, and the stand-off was less than the agreed profile. Approximately 450m of pipeline could have been affected by potential ground movement from instability of the slope face.

Subsequently, a geotechnical analysis was carried out to ensure that the integrity of the pipeline could be secured.

A Geotechnical Assessment Report, Design Proposal and an Earthworks Design were produced to provide long-term stability to the western face of the quarry.

Due to concerns the quarry operator had previously installed a protective Earth Berm, over a 100m’s long, to retain the western face of the quarry. However, this was not complete in line with the earthworks design, when inspected in March 2018.

A quarry inspection carried out by Cadent in September 2018 also noted that the quarry operator was approaching the end of the Earth Berm construction

SCOPE

Cadent wanted to investigate the effectiveness of the installed Earth Berm by monitoring ground movement and ongoing pipe stresses. They also wanted to identify any stresses that may have resulted because the western face of the quarry was not retained

Rayden Engineering (REL) were employed in the role of Principal Contractor under CDM 2015 to complete all works.

The overall objective was to establish the existing stresses and monitor the on-going strain and movement of the pipeline to determine the effectiveness of the installed Earth Berm.

SERVICES DELIVERED

Prior to site mobilisation a full risk assessment and method statement was completed to ensure a safe working environment once operations commenced.

Work took place on the edge of an arable field adjacent to the quarry. The working area was planted with maize which was removed before excavation works commenced.

A full line check was completed before works started and the pipeline and any known utilities were marked out.

As principle contractor REL:

- Agreed 5 critical locations along 450m pipeline, with Cadent, where excavations were carried out to expose pipework.

- Designed safe excavations to expose pipeline in consideration of ground conditions & quarry including Temporary Works Design (TWD).

- Positioned Temporary Bog Mat crossing & bypass points in accordance with our TWD.

- Prior to excavating, CAT scanned pipeline in accordance with HSE guidance HSG47 using a CAT4+ Cable Avoidance tool & pegged out identified pipeline route.

- Excavated & exposed pipeline / welds at 5 agreed location. Pipeline & welds identified in accordance with OLI/4 inspection processes.

- All excavations hand dug in accordance with GD-SP-SSW-22 Specification.

- Exposed girth welds inspected to understand quality along length of pipeline. Weld quality assessed in accordance with welding specification T/SP/P2 / T/PM/P/18. All welds were acceptable in accordance with T/SP/P/2.

- Area was off, marked up & pipeline prepared for P9 welding of Mounting Blocks, Ultrasonic inspection wall thickness & report & assessment of gauge locations.

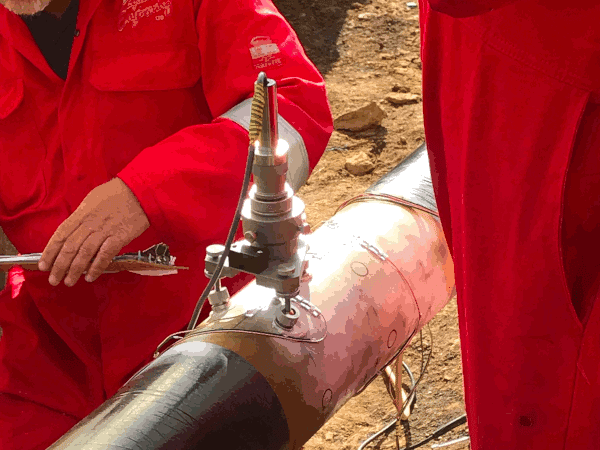

- Prior to installation of Strain Gauges, REL carried out Q10 inspection works at each of 5 locations to obtain material information for purposes of weld information; ROSEN were employed to carry out Q10 sampling works.

- Once each of 5 locations fully exposed, Strain Gauge equipment was welded onto pipeline in accordance with T/SP/P/9 welding procedures.

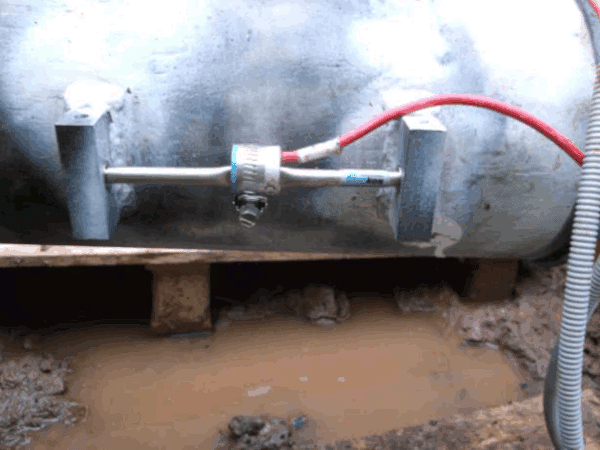

- ROSEN also commissioned to supply & install the Vibrating Wire Strain Gauges (VWSG) & logger complete with kiosk. REL excavated trenches & installed ducts for strain gauge cables to be brought into test post to collate data onto a data logger for long-term data capture.

- Installation & provision of Residual Stress Measurements (RSM) at 5 critical locations provided direct assessment of current stress/strain state in the pipeline. Strain in pipeline then calculated to provide datum stress state. Work carried out in accordance with GD/SP/GM/8.

- Following completion of above works, REL recoated affected areas with multi component liquid in accordance with CW5, & subsequently backfilled all excavations leaving site in the same condition as when we arrived.

REL fully engaged with Cadent and landowner representatives through regular communication and meetings. This helped build up a strong rapport and an honest, trustworthy relationship that ensured the smooth running of the project and all associated works.

As part of the contract and under CDM REL also provided

- Designed & executed excavation works in accordance with SW22 & Maint 5028 taking into consideration GD/PM/P/18.

- Installed all necessary Signing, Lighting & Guarding (STC) to protect general public & livestock, including temporary heras fencing.

- Provided traffic management for access/egress & delivery’s, access off main road to site.

- Provided welfare facilities under CDM 2015.

- Provided 24/7 security for site.

- Provided detailed programme of works determining sequence of works.

- Provided all required documentation needed as part of roles (e.g. Construction Phase Plan, H&S file).

- Provided RAMS to identify & control all known hazards & risks.

- Installed crossing points to access working areas due to shallow pipeline depth – designated crossing points installed as per T/SP/CE12.

- Carried out daily risk assessments & updated on site.

OUTCOME

The project was delivered within budget and on time without any major difficulties. All works were completed in line with the approved design and RAMS.

REL fully satisfied their duties under CDM 2015 and provided full handover on completion.

The CHRSM results generally showed low axial stresses on the pipeline, with some sagging due to depression in the land. None of the results showed evidence of the pipeline having significant horizontal bending stresses. However, it was expected if there had been any movement in the quarry wall this would have caused horizontal movement of the pipe and presented more prominently in the VWSG data.

While not ideal, the stresses recorded to date were below the acceptance criteria specified in GP/SP/GM/1.

Therefore, once the project was completed Topographical Survey Works were carried out for a further 12 months post project to provide Cadent with ongoing monitoring of ground movement to detect any additional loads that would affect pipeline integrity.