BACKGROUND

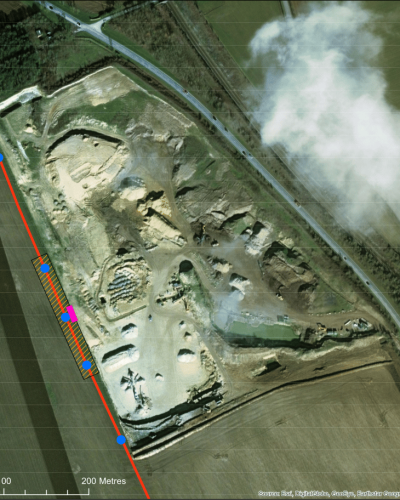

Rayden Engineering Limited (REL) were contracted by SGN to divert a 2.8-mile (4.5km) section of their existing 600mm (24”) P074 Marsh Gibbon to Newton Longville High Pressure (HP) pipeline near Calvert, Buckinghamshire.

Part of the existing pipeline needed to be rerouted to make way for the construction of the new High-Speed Rail Link (HS2). This allowed the diverted section to be upgraded with new pipework and supporting infrastructure.

The general location of the works was to the southwest of the village of Steeple Claydon in the Aylesbury Vale District Council area. The newly diverted pipeline route passed over semi-rural land, and therefore construction work had limited effect on the local community.

ABOUT SGN

SGN is a gas distribution company that delivers natural and green gas to over 6 million homes and businesses across Scotland and the South of England.

The company manages a network of underground gas pipelines covering more than 44,000 miles and has invested heavily in upgrading its network with new modern pipework.

SCOPE

REL were employed in the role of Principal Contractor, under CDM 2015, to complete all required works.

Work included:

- Construction of a new 600mm (24″) diameter cross-country gas pipeline diversion approx. 2.8 miles (4.5km) long.

- Construction of new Pressure Reduction Station (PRS) & Above Ground Installation (AGI).

- Intermediate Pressure (IP) and Medium Pressure (MP) modification works.

- Removal of existing above ground equipment at the now redundant PRS Steeple Claydon site.

SERVICES DELIVERED

All new pipework was constructed in accordance with IGEM/TD/1 Edition 5 and other applicable SGN Specifications.

The following activities formed the key components of this project:

600mm (24″) Pipeline Construction & Installation:

- All civil works required to construct the 2.8 mile (4.5km) pipeline diversion including working width preparation.

- All civil works needed for new PRS build including all excavation works, construction of bases for various new equipment i.e., skid units, buildings etc.

- Supply & erection of HERAS Fencing along complete perimeter route & for excavation, backfill & reinstatement.

- Excavation works completed to tie-in locations for P18 works.

- String, weld & laying of 600mm (24″) pipeline.

- Completion of Auger Bores & micro-tunnel techniques for crossing locations.

- Hot-tap welding (P9) to install stopple arrangement in preparation for tie-in operations.

- Fabrication & installation of by-pass pipework at tie-in locations.

- Completion of under-pressure drilling operations through specialist contractor.

- Completion of tie-in operations including capping of redundant pipework.

- Installation of IP Outlet from Calvert PRS to tie in to adjacent 150mm (6″) Steel & 250mm (10″) PE mains.

- Installation of 180mm (7″) PE MP Gas Main approx. 0.9 mile (1.5km) in length.

- Installation of 125mm (5″) PE MP Gas Main approx. 1 mile (1.7km) in length, run in same corridor as HP pipeline.

- Decommissioning of redundant assets including grouting of redundant pipework left in situ.

New PRS & AGI works included:

- Decommissioning, removal, demolition & disinvestment of equipment & pipework at redundant PRS site.

- Installation & commissioning of new pre-heat system, heat exchangers, filters, regulators & associated pipework for PRS site at new location Steeple Claydon.

- All civil works required to construct new PRS including all excavation works, construction of bases for various new equipment i.e., AGI, skid units, buildings, E&I kiosk generator, transformer, & meter kiosk etc.

- Additional ducting & pathways were also installed.

- All prefabrication & welding works completed to SGN specifications.

- 80% of pipework was prefabricated off-site at the REL HQ workshop & installed on-site to our agreed designs & programme.

- Prefabrication & installation of all pipe supports for new pipework.

- Installation of all new pipework & painting in accordance with NGN/P/A/10 & CW5 specifications.

- Construction of new access roads & paths.

- Supply & installation of new perimeter fencing for AGI.

- Backfilling & reinstatement of whole site following completion of all phases of work.

OUTCOME

REL successfully delivered the project by fostering a strong working relationship with SGN, built on open communication and trust. This collaborative approach ensured smooth project execution, meeting all programme specifications without any major issues. The works were completed on time, within budget, and fully aligned with the approved design and RAMS.

REL fulfilled all CDM 2015 obligations and provided a full handover in May 2019.